Commercial Range Hood Fire Suppression: A Complete Guide for Restaurant Safety

Kitchens are fire’s playground, but a well-designed commercial range hood fire suppression system keeps small flares from becoming major disasters.

In this guide to commercial range hood fire suppression, you’ll find everything on code requirements, key components, and maintenance best practices so your kitchen stays protected and compliant.

Key Takeaways

- A commercial range hood fire suppression system combines automatic wet-chemical discharge, fuel shut-off, and manual pull stations to swiftly control grease and cooking fires.

- Compliance with NFPA 96, ANSI/UL 300, and local codes ensures your system’s design, installation, and maintenance meet critical safety standards.

- Regular monthly checks and annual professional inspections keep detection heads, nozzles, and cylinders reliable, so your kitchen remains protected around the clock.

What Is a Range Hood Fire Suppression System?

A commercial range hood fire suppression system is a specialized kitchen fire suppression setup designed to detect and extinguish grease fires or flare-ups on cooking equipment before they spread into the ductwork or makeup air intake.

Automatic detection & response

Heat- or flame-sensitive links sit strategically above burners and griddles. When temperatures reach a critical point, they activate a wet-chemical cylinder, releasing a saponifying foam that cools flames and seals off vapors across your hood and ducts, providing an efficient first line of defense.

Fuel & power shut-off

Most systems integrate a fuel-shutoff assembly that automatically cuts gas and electrical feeds upon activation. By starving the fire of its energy source, these units not only control the blaze but also protect your property and staff from reignition so your commercial kitchens remain a safe, code-compliant workspace.

Regulatory & Code Requirements

Installing a reliable kitchen fire suppression system in commercial kitchens means meeting strict standards designed to keep your hood, cooking equipment, and staff safe. Here’s what you need to know:

NFPA 96: Commercial cooking protection

NFPA 96 sets the baseline for fire suppression in restaurant and institutional kitchens. It covers everything from system design and nozzle placement to monthly inspection checklists and annual testing.

You’ll also find requirements for integrating a manual pull station, so staff can trigger the discharge if automatic detection doesn’t engage fast enough.

ANSI/UL 300: Wet-chemical reliability

Since 2014, every hood system must comply with UL 300 pre-engineered wet-chemical standards (adopted under NFPA 17A). That means cylinders, nozzles, and agent formulations are tested together to ensure fast flame knockdown and minimal cleanup. Compliance guarantees your system can control grease fires efficiently and won’t fail when you need it most.

Local codes & permit coordination

Beyond national standards, local building and fire codes often mirror NFPA 96 and the International Building Code but can add unique permit-review steps or installation requirements.

Before you move forward, check with your municipality on plan submissions, inspection timelines, and any makeup-air upgrades required to keep your hood operating in accordance with local regulations.

Meeting these critical, worldwide-recognized codes ensures your fire suppression system delivers the protection and reliability customers expect, backed by formal inspection, testing, and a commitment to kitchen safety.

Key Components & Operation

A dependable commercial range hood fire suppression system combines specialized equipment and precise engineering to respond instantly when flames threaten your kitchen’s safety.

Detection heads

Heat-sensitive links or fusible bulbs sit directly above cooking appliances, like burners, griddles, and fryers. When temperatures hit a critical threshold, these links melt or break, triggering the suppression sequence. Their placement reflects your kitchen’s unique needs, ensuring even hidden hotspots in ductwork are monitored.

Control head & agent cylinder

At the heart of every system, the control head houses an activation valve connected to a pressurized cylinder of wet-chemical agent. Once a detection head trips, the valve opens, releasing a saponifying foam that cools burning grease and creates a sealing blanket that extinguishes fires quickly and prevents reignition.

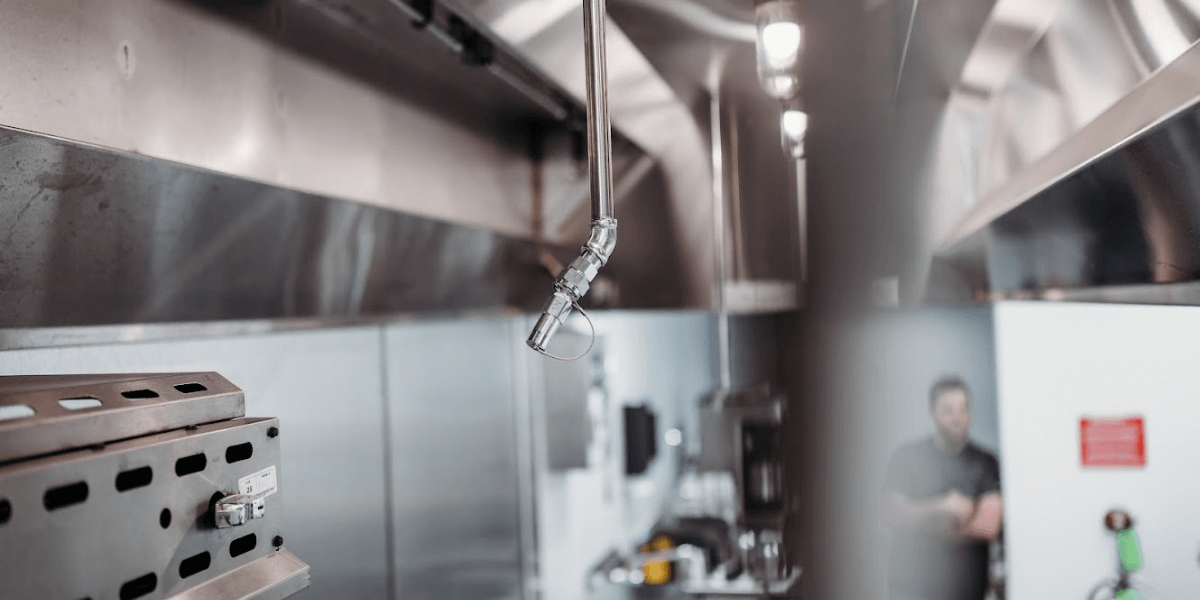

Nozzle piping

A network of stainless-steel piping delivers agent through strategically placed nozzles. These nozzles target the most vulnerable zones: directly over burners, inside the hood’s capture area, and at key points in the ductwork. Proper nozzle layout ensures full coverage, so your system can suppress fires no matter where they erupt in the hood’s airflow path.

Fuel-shutoff assembly

To starve the fire, many systems include an integrated fuel-shutoff assembly. On activation, it closes gas valves and cuts electrical power to cooking equipment. This automatic closure secures your property by halting fuel feed within seconds, giving your suppression system the edge it needs to control flames efficiently.

By understanding how each component works and how they interconnect, you can discover why these systems are the backbone of kitchen fire defense worldwide.

Suppression Agents & Applications

Choosing the right extinguishing agent ensures your system remains kitchen safe while meeting fire-suppression demands around the world.

Wet-chemical formulations

These potassium-based agents react with hot grease to saponify oils, creating a soapy, cooling blanket that smothers flames and prevents reignition under Type I hoods. Their low-pH formula minimizes corrosion in ductwork and keeps cooking areas safe for daily operations.

Clean agents (Optional)

In adjacent spaces like walk-in coolers, dry-storage hoods, or areas with sensitive electronics, non-corrosive clean agents (such as FK-5-1-12 or Novec™ 1230) can supplement your wet-chemical system. These agents extinguish fires without residue, preserving delicate equipment and ensuring a truly kitchen-safe environment even in unique, cross-functional zones.

Inspection, Maintenance & Testing

Regular upkeep keeps your commercial range hood fire suppression system reliable when it matters most.

Routine checks

Each month, perform quick visual inspections to confirm:

- Nozzles & piping: Clear of grease buildup so the wet-chemical agent can flow freely.

- Agent cylinder pressure: Gauge remains in the green zone, and the cylinder shows no dents or corrosion.

- Fusible links & detection heads: Pins intact and links free of buildup to ensure prompt activation.

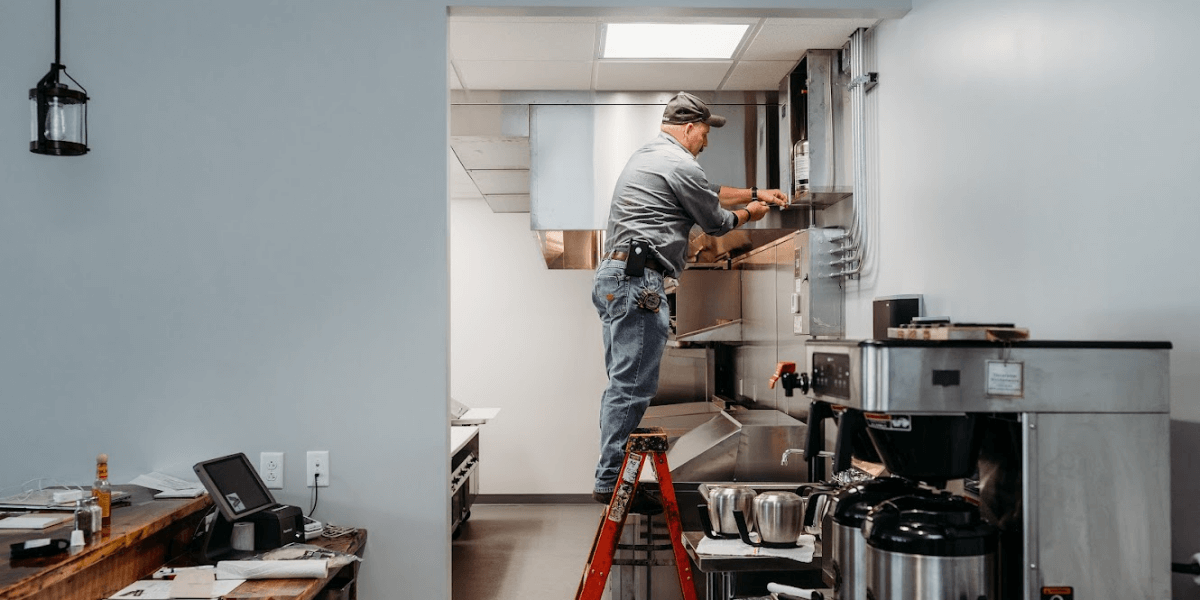

Professional service & record-keeping

At least once a year, schedule a certified technician to:

- Conduct a full system test, including manual pull-station activation.

- Perform hydrostatic testing on the agent cylinder per NFPA 96 §10.2.3.2 standards.

- Verify that fuel-shutoff assemblies and control heads function correctly.

Keep detailed logs of every inspection, discharge event, and component replacement. Proper record-keeping not only meets code requirements but also safeguards your kitchen with documented proof of maintenance and testing.

Selecting & Upgrading Your System

As your kitchen evolves, your fire suppression systems must keep pace so every piece of cooking equipment stays protected and your layout remains kitchen safe.

Tailor to your appliance mix & hood type

Start by mapping out every heat source beneath your hood: burners, broilers, fryers, griddles, or woks. Each appliance changes the volume and direction of grease-laden vapors, so nozzle spacing, spray patterns, and cylinder capacity need to match your exact setup. A small six-burner range demands a different piping network than a multi-station line with charbroilers.

By sizing your system to the unique needs of your hood coverage area, you discover reliable suppression performance every time.

Re-evaluate after layout changes

Planning a remodel or adding new equipment? Any change, like installing a wok station or shifting your hood’s makeup-air intake, requires a fresh system review and often permit amendments. Even a minor layout tweak can alter airflow, affecting how suppressing foam reaches hidden corners of ductwork.

Before you install new gear, update your suppression design, file revised plans with local authorities, and confirm your system still meets UL 300 and NFPA 96 requirements. That way, you maintain world-class protection without gaps in coverage.

Let's Fortify Your Commercial Kitchen’s Defenses

When it comes to commercial range hood fire suppression, don’t leave safety to chance. Swartz Fire & Safety's NAFED-certified technicians handle everything from custom system design and expert installation to thorough on-site inspections and code-compliant maintenance.

Reach out to us today to schedule your evaluation and ensure your restaurant’s cook line stays protected, efficient, and fully up to code.

Conclusion

A reliable range hood fire suppression system is your best defense against kitchen fires. By understanding requirements, choosing the right components, and keeping up with maintenance, you’ll protect your team, your property, and your peace of mind.

Frequently Asked Questions

What is a kitchen fire suppression system, and how does it work?

A kitchen fire suppression system is a specialized setup that is often integrated into a commercial range hood. It detects and extinguishes fires on cooking equipment.

Heat- or flame-sensitive links trigger a wet-chemical agent discharge directly over burners and ductwork, while a fuel-shutoff assembly cuts gas and electrical feeds. This combination rapidly cools grease fires and prevents reignition without manual intervention.

How often should I schedule inspection and maintenance for my commercial range hood fire suppression system?

You should perform quick monthly checks yourself—verifying nozzle clearances, cylinder pressure, and fusible-link integrity—and arrange a full professional inspection at least once a year.

Certified technicians will test the manual pull station, conduct hydrostatic tests on the agent cylinder per NFPA 96 §10.2.3.2, and log every maintenance step to ensure ongoing reliability and code compliance.

Does every kitchen fire suppression system require a manual pull station?

Yes. In addition to automatic activation, NFPA 96 mandates a manual pull station for all commercial kitchen fire suppression systems. This lever allows staff to discharge the wet-chemical agent immediately if an automatic detector fails or if they spot a fire before heat links reach their activation threshold.

Can a commercial range hood fire suppression system handle all types of kitchen fires?

While these systems excel at controlling grease-based Class K fires and common Class A, B, and C hazards under Type I hoods, they’re not designed for Class D metal fires in workshops or large-scale industrial blazes.

For full coverage, pair your hood system with additional extinguishers, such as Class D units for metal fires, strategically placed throughout your facility.